Extendable Laptop Case

In 2014 I led a team of 4 engineering students in the design of a polycarbonate laptop case with a slide-out work surface providing on-the-go “desk space”. Focuses of the project were design for manufacturing (injection molding, aluminum extrusion) and use of finite element analysis to guide design.

What

ENG1931D - Design of Mechanical Assemblies Final Project, Brown University

My Role

Team lead

Finite Element Analysis (FEA) lead

The Team

Ahyoung Choe (biomedical engineering) Daniel Tonderys (mechanical engineering) Tyler Smith (mechanical engineering)

Motivation

I had observed students in lecture halls and on the commuter train struggle with using both a laptop and notebook at the same time. Polycarbonate laptop cases such as the Speck Smartshell Case were extremely popular at the time, so I wondered if we could develop a similarly low-profile laptop case that would not only protect the laptop, but also provide additional workspace for working in lecture halls, outdoors, on trains and buses and other space-limited situations.

Students using phones or notebooks along with their laptops at non-desk settings

Design

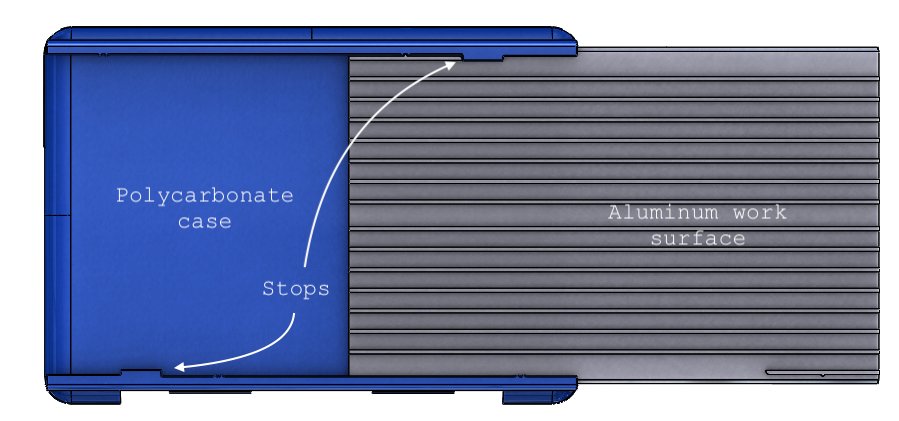

The design consists of a 2-3mm thick polycarbonate case that snaps onto the frame of a 13” Macbook Pro. The underside of the case contains a slide-out aluminum slate providing an additional 20x30cm work surface. The slate can slide out on either the left or the right, and is held in place by stops in the plastic frame. 6061 Aluminum was chosen for its rigidity, strength-to-weight ratio and heat dissipation properties.

Profile View of case. Aluminum slate is directly beneath the laptop. It is ribbed to increase rigidity while minimizing weight

View from underside. Note that work surface can be pulled out to either side, but stops prevent it from being fully removed.

Close up view of case corner

Case bottom without laptop

Finite Element Analysis

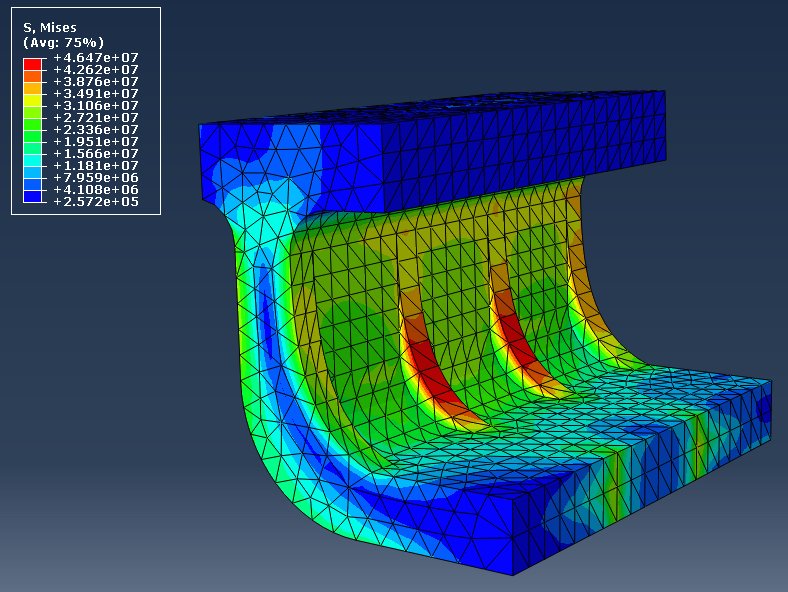

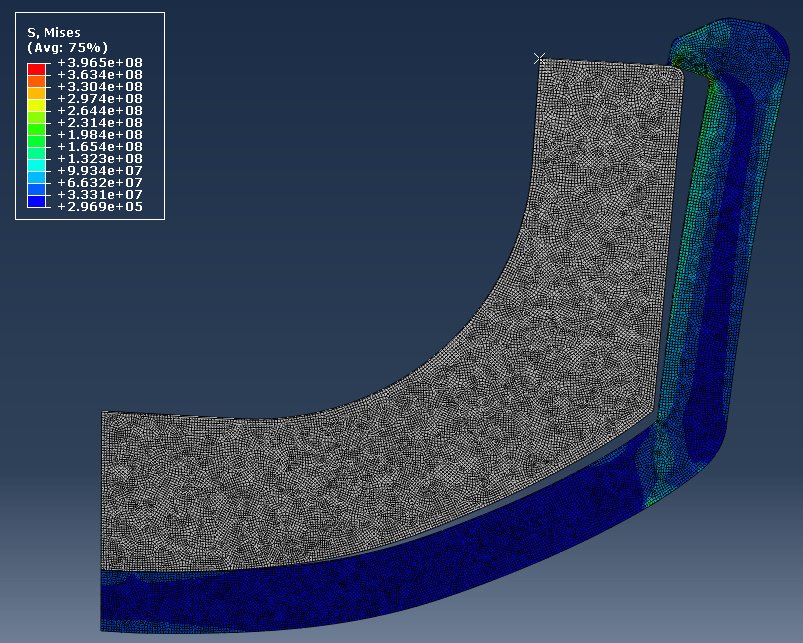

I conducted the stress/strain analysis on various parts of the case, using Abaqus to run FEA simulations, and iterating on material selection and geometry. A challenge was designing the case to be rigid enough to support the slide-out work surface, yet flexible enough to clip onto the laptop. Additionally, since the case was to be injection molded, it needed to have an even wall thickness throughout to prevent warping during manufacturing. Multiple iterations eventually led to a design using ribbed supports on the underside of the case, and polycarbonate with a 30% glass fill (adding glass to polycarbonate is one way to increase its rigidity).

Stress simulations of underside brackets with different rib designs (left, center), and clips holding case to laptop (right)