The Self-Spotting Weight Rack

A safer way to lift weights

I led a team of 3 in the design and prototyping of an exercise machine that allows athletes to weight train independently without fear of injury.

What

Final project for ENG1000 (Engineering Design) at Brown University

My Role

Design engineer, team lead

The Team

Richard McDonald (mechanical engineering), Matthew Miller (mechanical engineering)

Summary

I led a team of three mechanical engineering students in the design of a squat rack that allows full range-of-motion squats without the need for a spotting partner. The squat rack consists of a suspension system from which hangs a Barbell. When the user squeezes grip sensors on the bar, the suspension system releases, and the user can squat as they would normally with a free barbell. At the end of their set, or in the event of failure, the user releases their grip, and the suspension system reactivates. The design eliminates a key disadvantage of existing exercise machines, which limit users’ range of motion resulting in less muscle activation.

Bar hangs suspended by cables

User positions themself under bar

Grip sensors allow bar to be lowered; user squats

When finished or failing, releasing grip causes cables to lock

Background

The free weight squat is widely considered the single most valuable exercise for athletes seeking to increase strength. However, solo heavy squatting can be dangerous, and as a result, athletes train with spotting partners to avoid injury. The idea for a weight rack that could “spot” itself came about from talking with varsity athletes at Brown, who were hesitant to train off-season at their 1-rep-max limit (the most weight an individual can lift for one repetition) without a spotting partner.

Many gyms today have machines that allow squat like motions without the need for a spotter; the most common of these being the Smith machine, a device where a barbell moves along two guided rails; rotating the barbell causes it to lock in place. However, these machines all suffer from the same flaw: by eliminating the need of the lifter to stabilize the barbell, they reduce total muscle activation and fail to train stabilizing muscles. A 2009 study in the Journal of Strength and Conditioning found that leg muscle activation was 43% higher with free squats than with a Smith machine for equal levels of perceived exertion.

Illustration of a Smith machine

A powerlifter with 2 spotters. Used with permission from SoCal Powerlifting

Design constraints:

Budget: Our team was allotted $500 to develop a functioning prototype

Timeline: 10 weeks

Safety & reliability: The design should be safe to use, and withstand strains of a gym environment

Ease of use: the design should be no harder to use than a traditional squat rack

Effectiveness: The design must allow a user to perform an uninhibited free weight squat

Aesthetics: The design should appear to be sturdy and robust to gain user trust. There is an aesthetic culture associated with weightlifting gyms and the design should fit in.

Retraction & Locking

Not wanting to reinvent the wheel, we surveyed retraction and locking mechanisms used in seatbelts, climbing equipment, and sailing, pulling inspiration from a number of existing designs. Most of these mechanisms, however, rely on stopping objects that are moving rapidly or accelerating, such as a falling climber. Because weightlifters often lower a bar rapidly when lifting we could not rely on a mechanism that prevented rapid movement.

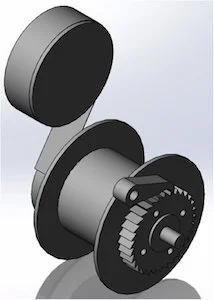

We developed a design that uses a ratchet and pawl system for locking and a coil spring for retraction. The coil spring provided sufficient range and near-linear force to keep the cables taught without aiding the lifter. We created a handle that controlled the pawl via a Bowden cable, a mechanism similar to how bike brakes work.

Locking system in an Auto-Belay Device

Our retraction and locking system design consisted of a coil spring (top), a barrel around which suspension cable coils (bottom), and a ratchet and pawl (bottom right)

Rendering of our handle design

Prototyping:

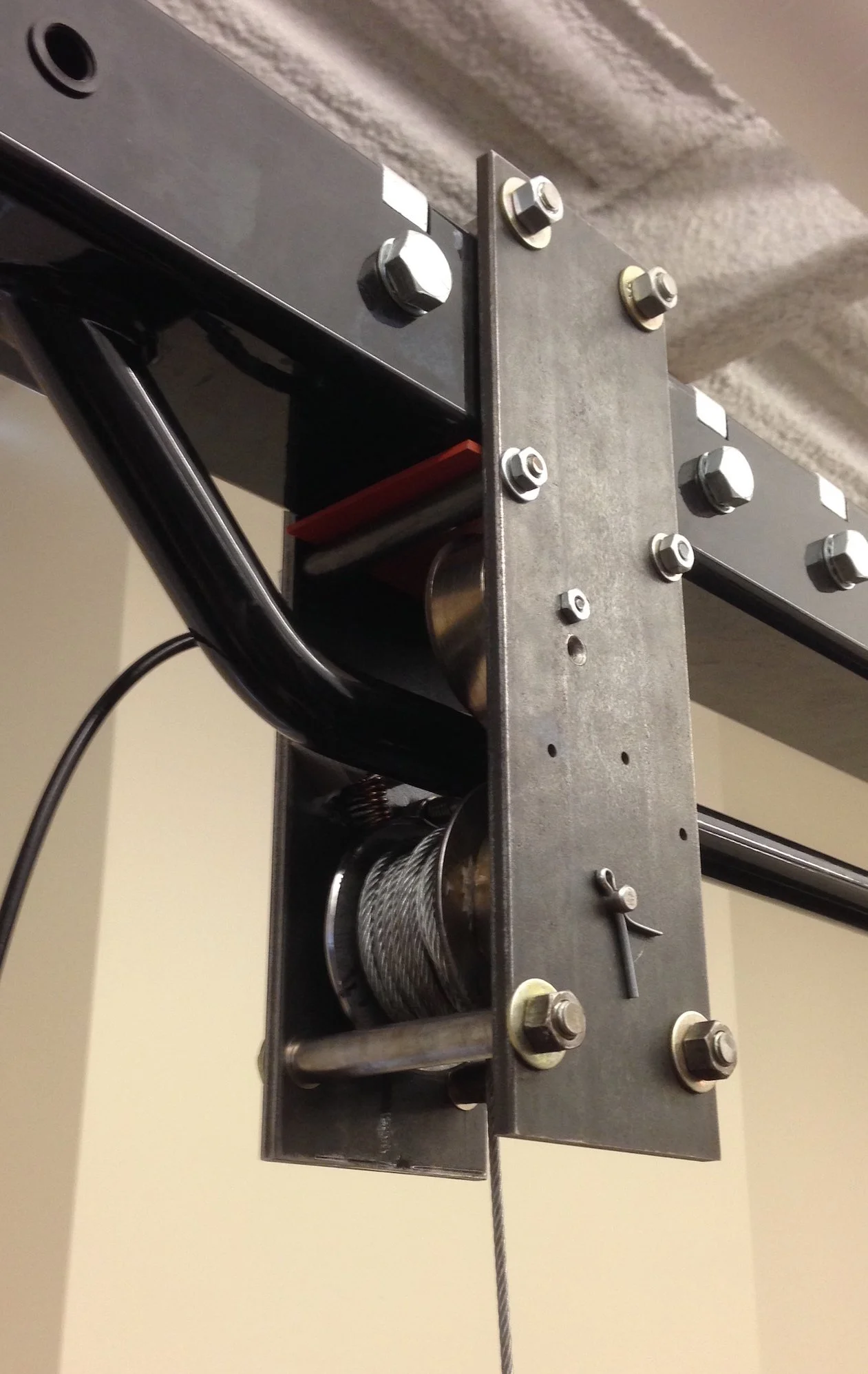

We developed a functional prototype that attached to an existing squat rack, using 3D printed, wire EDM cut and machined parts, as well as purchased springs, ratchet wheels, cables and hardware. Our prototype was capable of supporting weights up to 600 lbs.

3d Printed handle

Retraction & locking system prototype

Testing

We set up our prototype in one of Brown’s varsity weight rooms, allowing athletes to test out the device. Many were enthralled with the device, and also provided valuable feedback for future designs, including a desire to have the handles be more easily adjustable in order to fit different size athletes performing different lifts.

A varsity wrestler testing our prototype