PCR Well Plate Flattener

During an internship at the Dittmer Virology Lab at the University of North Carolina, I supported a team of scientists by programming liquid handling robots to automate PCR analysis for virology studies.

One challenge of automating PCR analysis is that the repeated heating and cooling necessary to stimulate DNA replication often warped the microplates used to hold samples. This meant that a robot pipetting in a given well might insert too high or too low, failing to extract the sample or damaging the pipetting head.

Dr. Dittmer was in the process of purchasing a new liquid handling robot, and with it a $15,000 vacuum system which could flatten microplates that had warped from thermal cycling. He asked for my help in evaluating the robot prior to purchase.

I felt that the vacuum system was an unnecessarily complex solution to the problem of warped microplates, so took one of the warped plates home to experiment. I observed that the plate had a thin lip on its lower edge, and set about designing a device that could grip that thin edge in order to hold hold the plate flat. I bought some plexiglass and fabricated a prototype that weekend, which I showed to Dr. Dittmer on Monday. After testing it out on one of the lab’s robots, he cancelled his order of the vacuum system, instead asked his lab supplier to make him a set of mechanical adapters like mine, which they sold to him for a few hundred dollars; saving him and the lab thousands of dollars.

A liquid handling robot at Dittmer Lab

A 384-well microplate used for PCR assays. Liquid handling robots use sets of pipetting needles to pick up, deposit, and mix samples into each well with extreme precision.

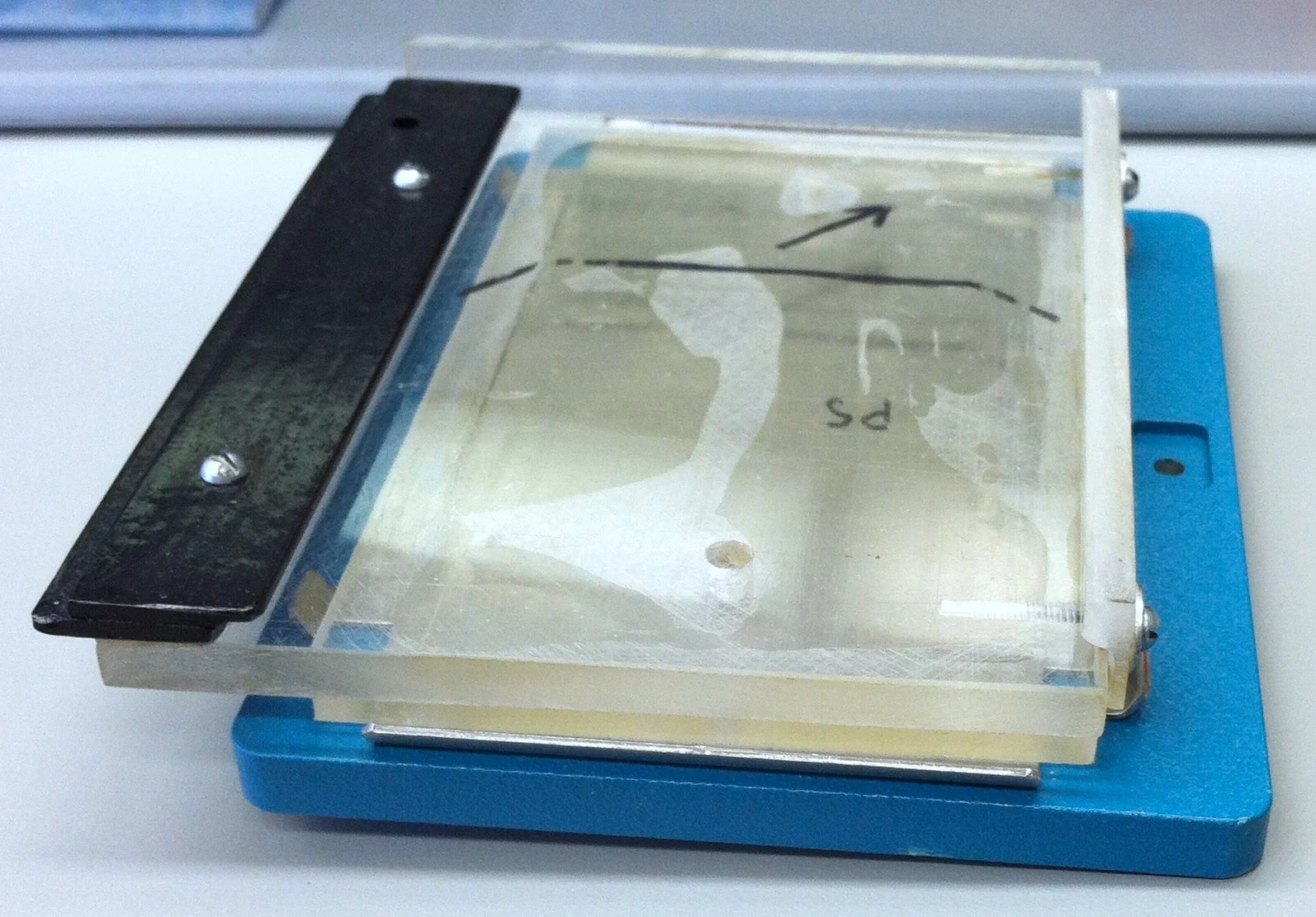

My prototype, made with cut plexiglass, aluminum bar, screws & superglue. Shown at right holding a microplate flat.

Version from lab supplier. Shown at right in use on a liquid handling robot.